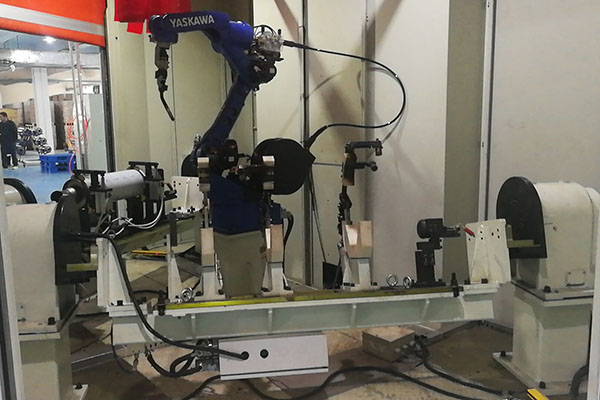

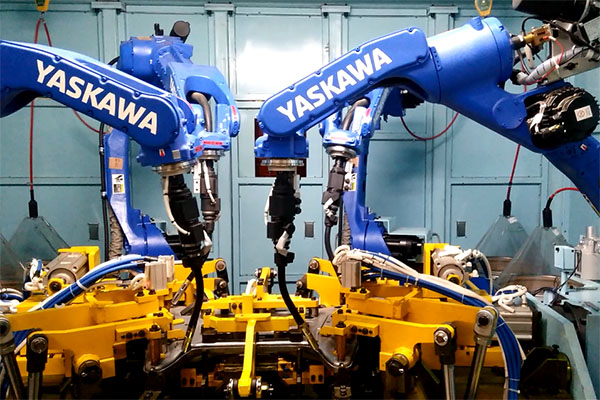

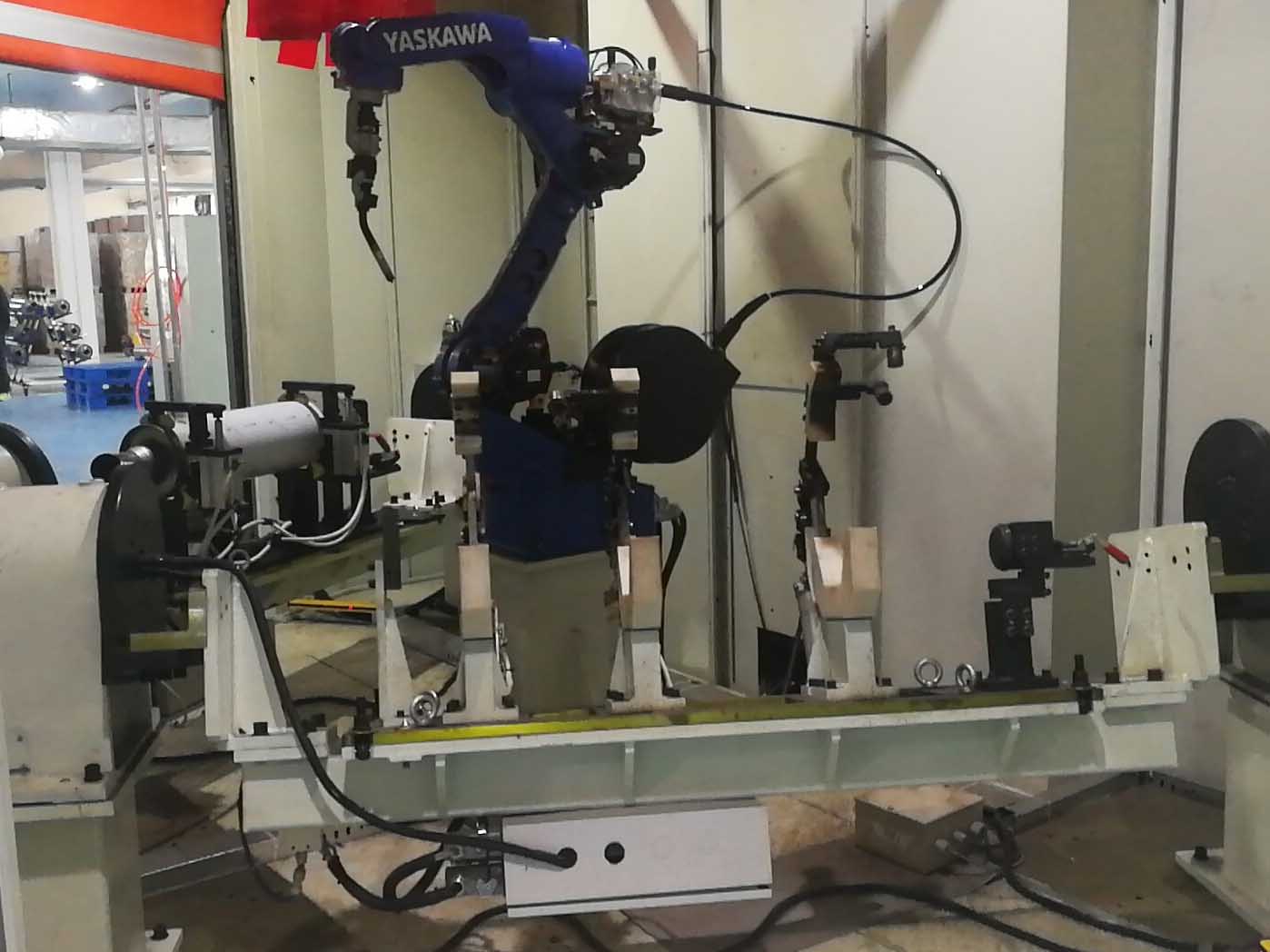

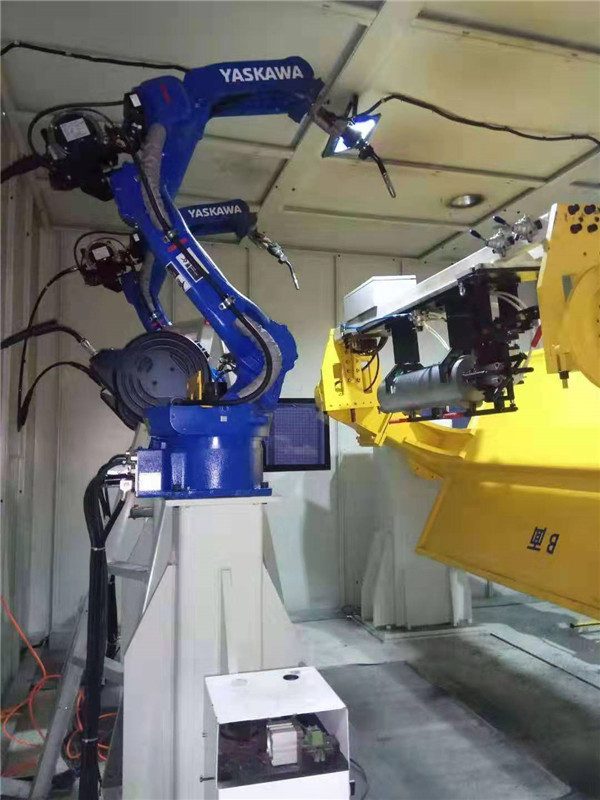

Welding robot workcell /welding robot work station

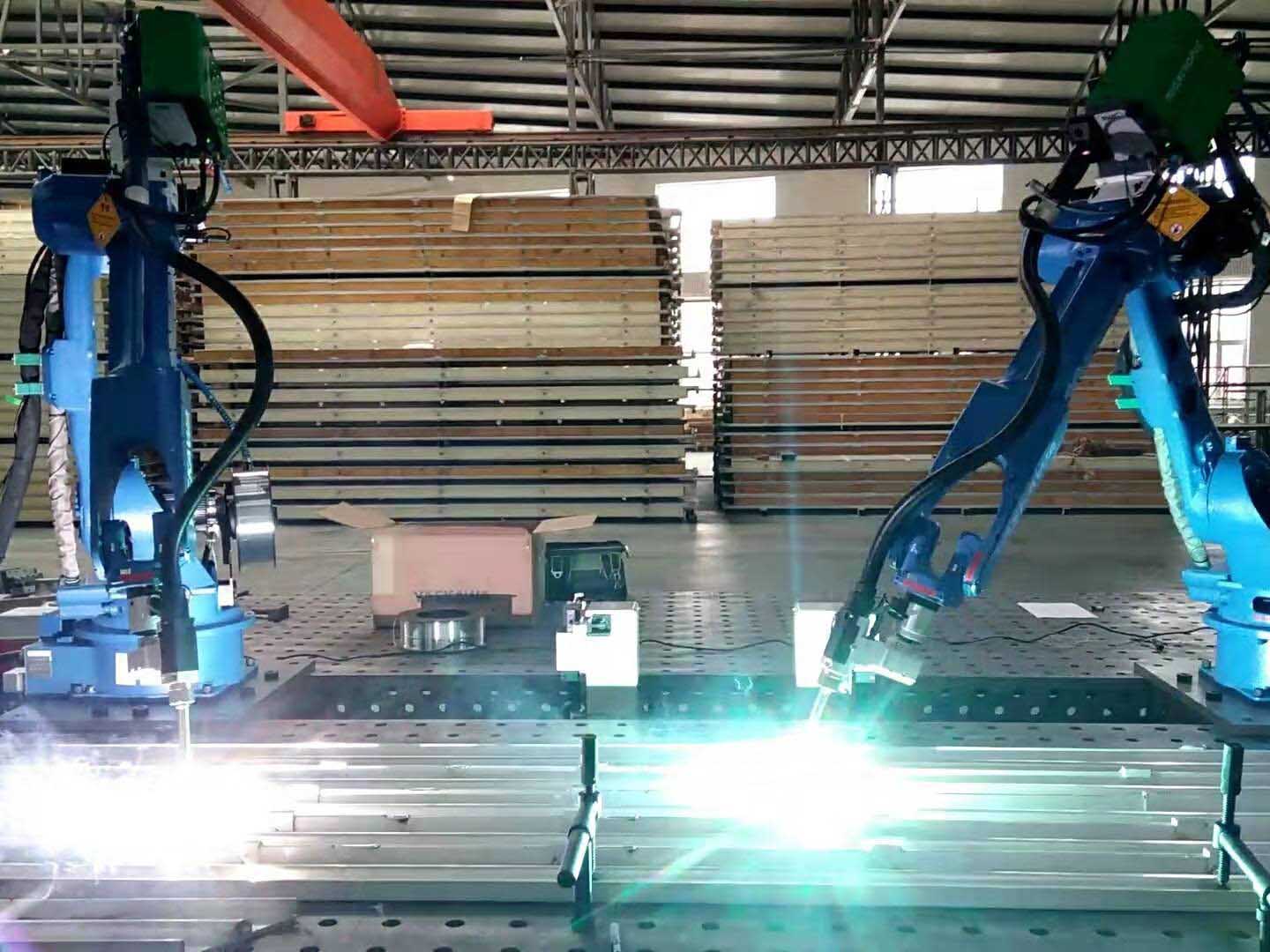

Welding robot workcell can be used in manufacturing, installation, testing, logistics and other production links, and are widely used in automotive vehicles and auto parts, construction machinery, rail transit, low-voltage electrical appliances, electricity, IC equipment, military industry, tobacco, finance, medicine, Metallurgy, printing and publishing industries have a wide range of applications. It not only facilitates corporate supervision, saves costs, but also guarantees welding quality, stable efficiency, and high safety performance. It is the choice of a wide range of users.

As a technological part of the welding process, the welding robot workstation becomes a "station" with welding function on the production line. It is a relatively independent control system, all operations or actions of the robot are completed by the control system of the welding robot itself.

In addition to welding robots, welding robot workcell also have ground rails, positioners, turning tables, weld tracking systems, safety fences, gun cleaners, safety systems, and peripheral equipment that work with welding robots.

When the welding robot workstation is working, the robot control cabinet receives external signals, such as welding, teach pendant, external control cabinet, etc., and transmits the data to the robot, so that the welder can reach the welding position and complete the welding task. The welding gun uses the high current of the welding machine and the heat generated by the high voltage is concentrated at the welding gun terminal to melt the welding wire and make it penetrate into the parts to be welded. After cooling, the welded objects are firmly connected into one body. The wire feeder can continuously and stably send out the welding wire according to the set parameters, so that the welding can be operated continuously and the welding efficiency is improved. It is matched with the gun cleaning station to clean the welding slag, spray anti-spatter liquid and trim the welding wire to ensure high-quality welding effect.

The external control cabinet of the welding robot controls the positioner, and transmits motor parameters and data to the control cabinet. The motor drives the weldment to stop rotating, so that the weldment reaches a proper welding position and assists the completion of welding.