-

The XYZ-axis gantry robot system not only retains the welding accuracy of the welding robot, but also expands the working range of the existing welding robot, making it suitable for large-scale workpiece welding. The gantry robotic workstation consists of a positioner, cantilever/gantry, welding ...Read more »

-

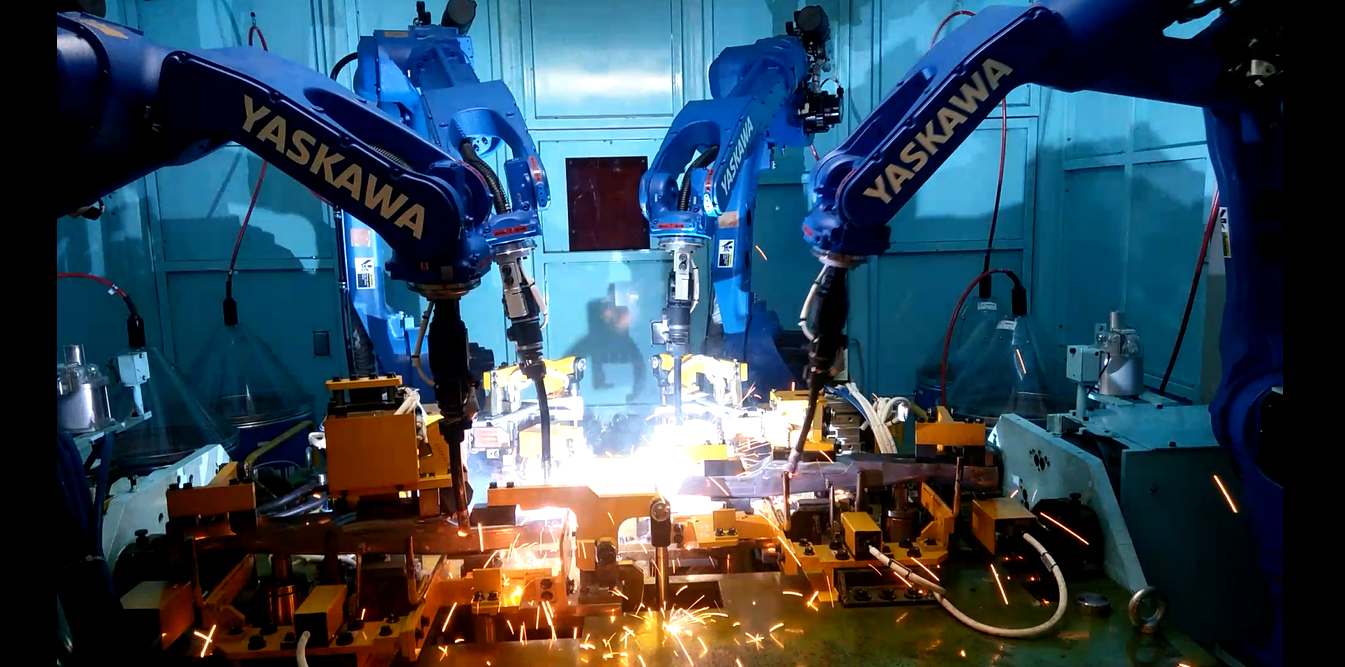

The robot welding workstation customized for our Australian customer with laser positioning and tracking, including the ground rail locator, has been shipped. Being first class distributor and after sale service provider authorized by Yaskawa, Shanghai Jiesheng robot Co.,Ltd is a robot system int...Read more »

-

On October 10th, an Australian client visited Jiesheng to inspect and accept a project featuring a robotic welding workstation with laser positioning and tracking, including a ground track positioner. Read more »

-

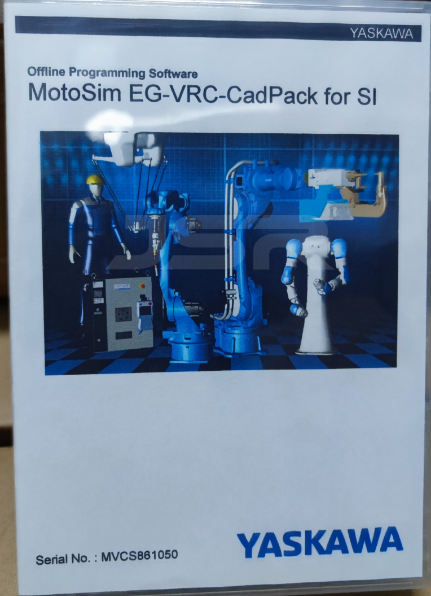

#Robotprogramming #yaskawarobotprogramming #Robotoperation #Robotteaching #Onlineprogramming #Motosim #Startpointdetection #Comarc #CAM #OLP #Cleanstation ❤️ Recently, Shanghai Jiesheng welcomed a customer from Australia. His goal was crystal clear: to learn how to program and proficiently opera...Read more »

-

September’s team building activity concluded perfectly, and in this journey filled with challenges and fun, we shared unforgettable moments. Through team games, water, land, and aerial activities, we successfully achieved the goals of sharpening our team, boosting our determination, and upl...Read more »

-

Among the four major robotic families, Yaskawa robots are renowned for their lightweight and ergonomic teach pendants, particularly the newly developed teach pendants designed for the YRC1000 and YRC1000micro control cabinets.DX200 Teach PendantYRC1000/micro Teach Pendant,Practical Functions of ...Read more »

-

At the exhibition site in Essen, Germany, JSR Shanghai Jiesheng Robot CO., LTD welcomes friends to come and exchange ideas,our booth is Germany Essen Locksmith Locksmith, Norbertstraße 17, 45131 Essen, Deutschland. For more information, pls contact: Sophia whatsapp: 0086137 6490 0418 www.s...Read more »

-

We are thrilled to announce that Shanghai Jiesheng Robot Co., Ltd. will be participating in the upcoming Welding and Cutting Exhibition to be held in Essen, Germany. The Essen Welding and Cutting Exhibition is a significant event in the welding domain, taking place once every four years and co-ho...Read more »

-

In the design of welding Gripper and jigs for welding robots, it is essential to ensure efficient and precise robot welding by meeting the following requirements: Positioning and Clamping: Ensure accurate positioning and stable clamping to prevent displacement and oscillation. Interference Avo...Read more »

-

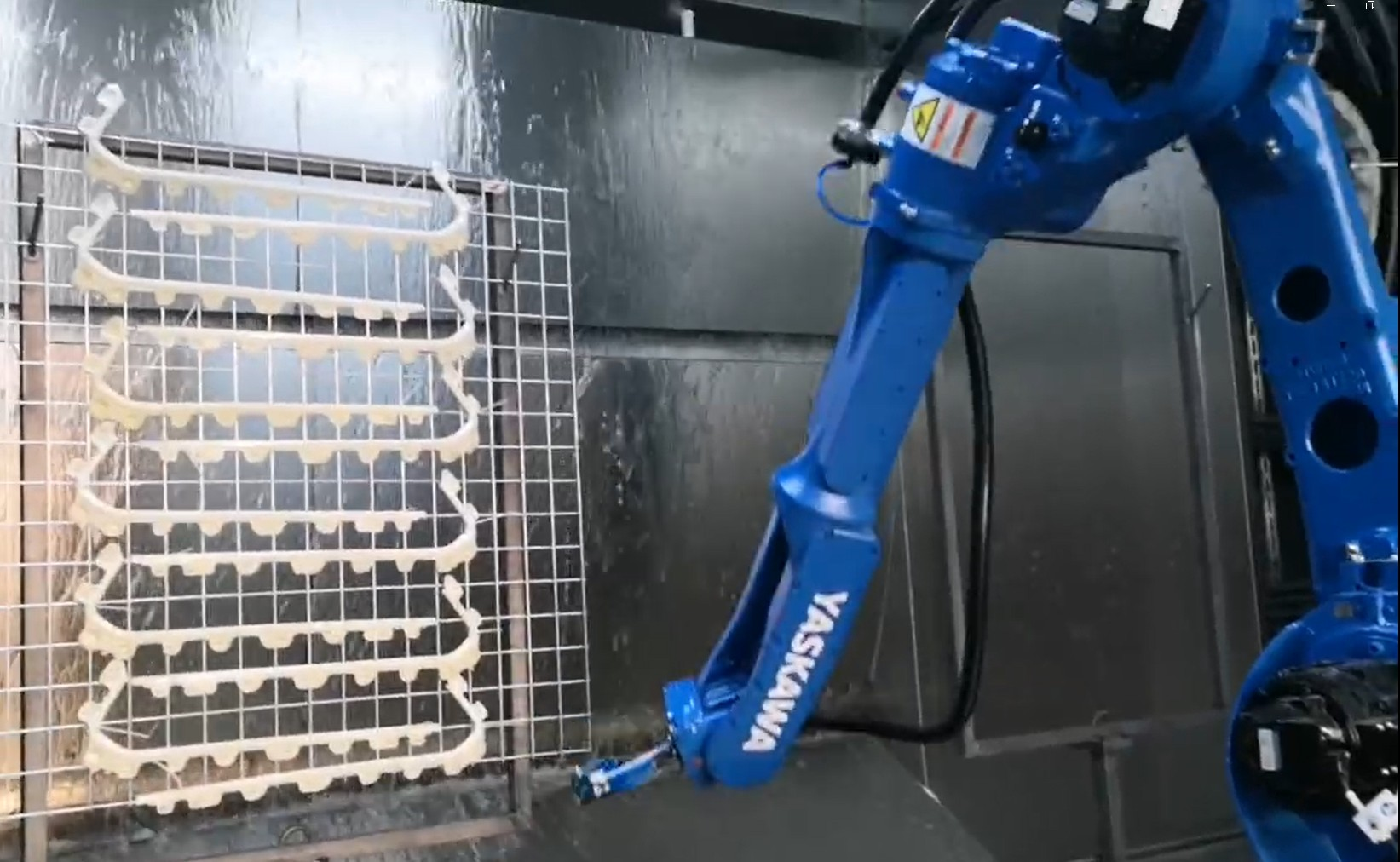

Friends have inquired about robotic automation spray systems and the differences between spraying a single color and multiple colors, mainly concerning the color change process and required time. Spraying a Single Color: When spraying a single color, a monochrome spray system is typically used. ...Read more »

-

Robots are widely used in various fields such as welding, assembly, material handling, painting, and polishing. As the complexity of tasks continues to increase, there are higher demands on robot programming. The programming methods, efficiency, and quality of robot programming have become increa...Read more »

-

-封面.jpg)

Using industrial robots to assist in opening new cartons is an automated process that reduces labor and enhances work efficiency. The general steps for the robot-assisted unboxing process are as follows: 1.Conveyor belt or feeding system: Place the unopened new cartons on a conveyor belt or feedi...Read more »

www.sh-jsr.com

Hot Products - SitemapYaskawa Spot Welding Robot, Palletizing Robot, Yaskawa Painting Robot, Welding Robot, Robot Palletizer, Automatic Painting Robot,

Get the data sheet or free quote

Write your message here and send it to us