The difference between robot laser welding and gas shielded welding

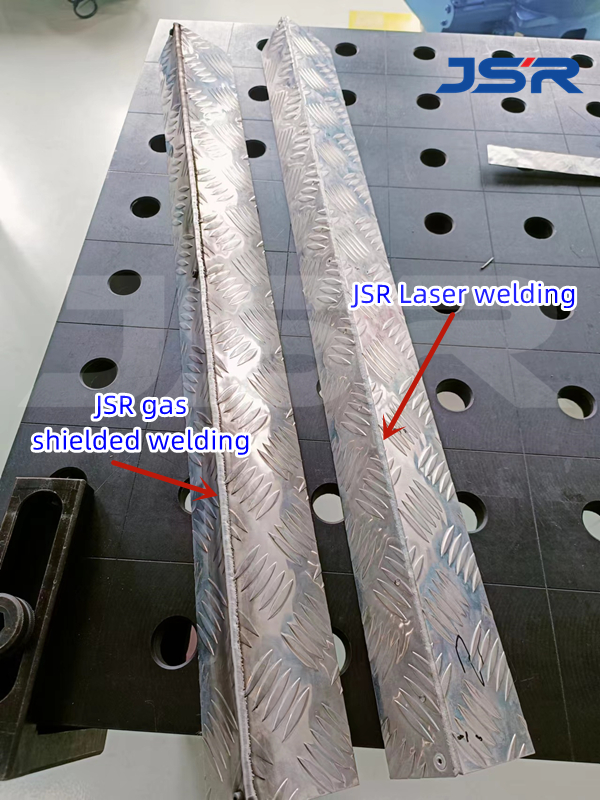

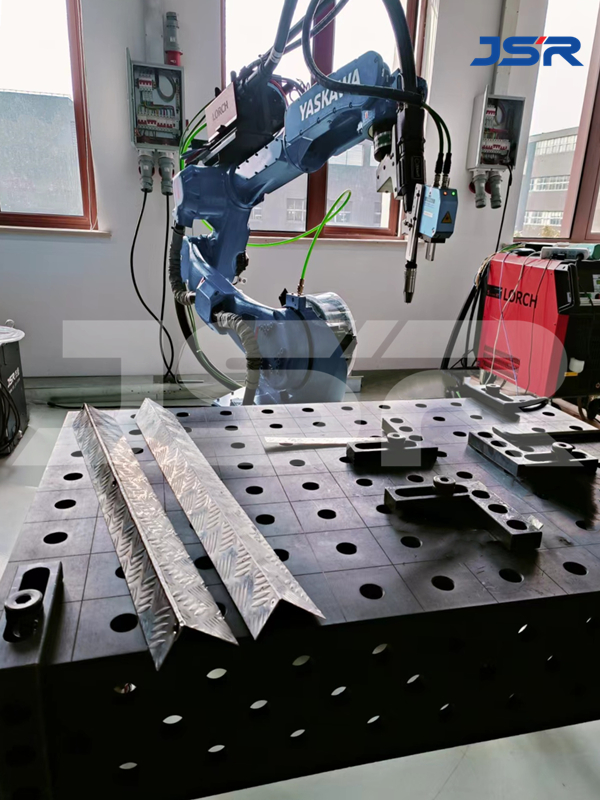

Robotic laser welding and gas shielded welding are the two most common welding technologies. They all have their own advantages and applicable scenarios in industrial production. When JSR processes the aluminum rods sent by Australian customers, it uses these two methods for welding testing. The following is a comparison of the welding effects of the aluminum rods, as shown in the figure:

What is laser welding?

Robotic laser welding: The laser beam is used to heat the weld seam to a melted state, and high-precision welding is achieved through accurate positioning of the laser welding head.

What is Gas shielded welding?

Gas-shielded welding: A welding gun is used to generate high temperatures through an electric arc, causing the welding material to melt while the welding area is protected from oxygen and other external contaminants by a shielding gas (usually an inert gas).

https://youtube.com/shorts/Hfyqm0_tJ6c

Robot laser welding VS Gas shielded welding

1. Applicable materials:

• Robot laser welding: More suitable for thinner materials, such as stainless steel, aluminum alloy, etc.

• Robot Gas-shielded welding: Has wider applications on thicker metal sheets, including steel.

2. Welding speed:

• Robotic laser welding: Usually welding speed is faster and suitable for high-volume production environments. The workpiece welding speed of JSR customers is 20mm/s.

• Gas-shielded welding: The welding speed is generally slower than laser welding, but it is still an important choice for some special workpieces and scenes with higher requirements. The workpiece welding speed in the picture is 8.33mm/s.

3. Precision and Control:

• Robot laser welding: Laser welding has high requirements on products. If there are gaps in the joints, it will affect the laser welding. It has a high degree of precision and controllability, and is suitable for occasions that require extremely high welding quality.

• Gas-shielded welding: It has a high fault tolerance rate for products and can be welded even if there are gaps in the product splicing. The accuracy is slightly lower than that of laser welding, but it can still be used in some applications with looser requirements.

4. Welding effect:

• Robotic laser welding: Due to the small heat input, laser welding has less thermal impact on the workpiece, and the weld seam has a flat and smooth appearance.

• Gas shielded welding: Due to the high welding temperature, the welding surface is easy to bulge, so it is suitable for workpieces that require polishing.

The choice of robotic laser welding or gas-shielded welding depends on specific production needs, including considerations of materials, welding quality requirements, production efficiency, follow-up processing, etc. In some scenarios, the two can also be used together to give full play to their respective advantages.

Post time: Jan-23-2024