Robotic workstations are a hallmark automation solution capable of performing more complex tasks such as welding, handling, tending, painting and assembly. At JSR, we specialize in designing and creating personalized robotic workstations for a variety of applications based on our customers’ needs and requirements while optimizing costs and increasing performance.

What Are Robotic workstations?

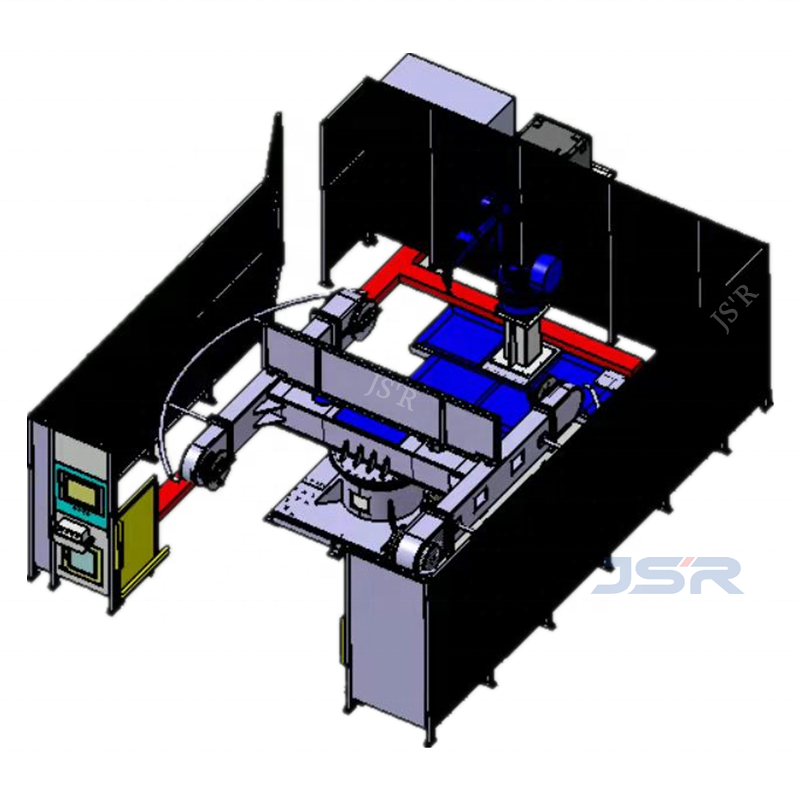

Robotic workstations contain components that are needed for a robot, or multiple robots, to perform tasks on a dismantling and palletizing line. These tools may include 3D vision camera, gripper, , synchronous tracking board, track/rail, positioner, and more. Instead of spreading out each step at different stations, robotic workstation setups perform the entirety of a process in the station.

At their core, assembly robotic workstations manipulate components into a specific position or into an assembly for future packaging, shipping, or use. Along with this functionality, JSR can design robotic workstations that take on finishing processes such as:

Transporting items: Robotic workstations can be outfitted with automated equipment to note when an assembly task has been completed and move the assembly to the next station in the industrial process.

Why Use Robotic workstations?

Automation is an advantageous addition to almost any industrial process because it adds speed, increases worker safety, and reduces the risk of human error or inconsistency. Robotic workstations are even more beneficial because they can handle complex tasks and manage both the assembly stage in its entirety and the transition to the next stage. Some of the specific benefits of robotic workstations include the following:

Efficiency

Automated processes can perform longer without increasing the likelihood of errors or inconsistent work quality. Even when automated assembly tasks take longer than manual processes, which is rare, the increased duration results in more assembled products.

Consistency

Robotic workstations follow set instructions and specifications to perform tasks and ensure the work meets the set standards. This results in more consistent output from start to finish, even as assembly tasks become more complex. Using robotic workstations for finishing tasks, such as welding, results in a more consistent product.

Savings

Robotic workstations increase the cost-efficiency of assembly projects. Automated tools work longer and faster than manual processes and don’t require wages, benefits, or other auxiliary costs. As technology continues to increase, creating, maintaining, and repairing robotic systems becomes more affordable.

Safety

Robotic workstations handle tasks that might otherwise pose a danger to human workers, including tasks that use sharp tools, processes that use caustic or toxic chemicals, and steps with heavy machinery or parts. Because the robotic workstations are directly manipulating the products, the operator comes into contact with very few potential hazards. At JSR, we build our robotic workstations so the robotic parts themselves also pose very little danger to the operator. Each cell can include safety features such as fencing, shields to block arc glare, emergency stops, and scanners.

Contact JSR for Robotic workstations Today

Robotic workstations increase the productivity and safety of facilities that handle assembly operations. At JSR, our experienced team of robotic specialists can design custom robotic workstations that handle both standard and unique assembly processes for your business. Contact us today to get started.

Check Out Our Case Study Below

what was our customer’s problem?

Our customer need to remove plastic particles from bags (50 kg each)

Our solution:2

We used a robot with a 180 kg capacity. 3D vision camer and custom robot gripper,It supports bag breaking of different sizes. The 3D vision camera takes a single photo to obtain 3D information of the entire layer of sacks. It is fast and efficient. The robot grabs and breaks the bag machine equipment, plus shaking, to effectively clean up the remaining materials.

Post time: Dec-07-2023