Industrial robot is a programmable, multipurpose manipulator designed to move material, parts, tools, or specialized devices through varied programmed motions for the purposes of loading, unloading, assembling, material handling, machine loading/unloading ,welding/painting/palletizing/milling and other manufacturing operations. They are used in assembly lines and other manufacturing applications,wherever materials need to be handled.

In response to client inquiries regarding robotic welding,JSR takes you to explore robot welding,and advantages & the common techniques employed in the process.

What is robot welding?

The automation of the welding process by robots is robotic welding. the robots perform and manage welding tasks based on the program and are capable of being reprogrammed as per the intended project.Robots are suitable for high-volume and repetitive tasks.

https://www.sh-jsr.com/robotic-weldiing-case/

How does robotic welding work?

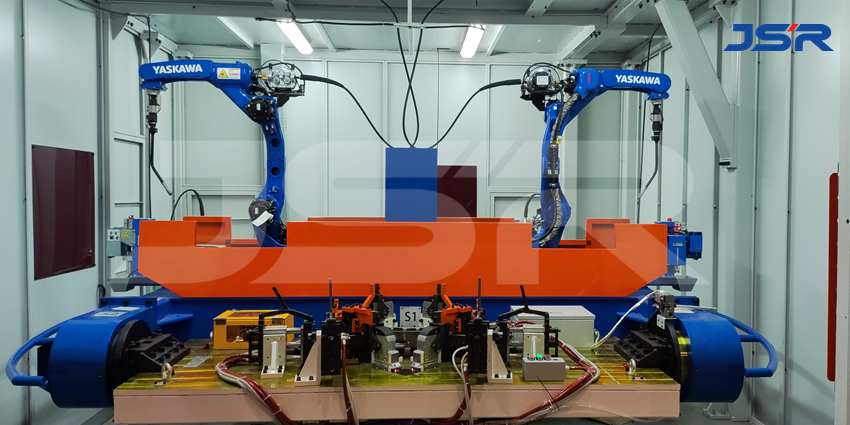

Welding robots, in particular, incorporate an arm that is capable of moving in three dimensions and welding metals together. There is a wire feeder that sends a filler wire to the robot, and a high-heat torch towards the end of the arm that melts metals during the welding process.Engineers maintain the robots and issue instructions to them.There is a control cabinet, which the operator uses to control the robot’s programs.A wire feeder supplies extra metal wire to the arm and torch as needed.

In addition, the welding robot workstation can be equipped with welding machines, positioners, ground rails, gun cleaning stations, laser equipment, arc shields, etc. JSR provides customized welding integration solutions according to customer needs.

What are the advantages of robotic welding?

precise results, less wastage, and improved safety,Improve productivity and control delivery time more accurately.These robots can reach locations that are inaccessible by human hands and perform complicated tasks much more precisely.

What are the common welding processes?

TIG Welding,MIG Welding,MAG Welding,ARC Welding,Spot Welding,Laser Welding,Friction Welding,Stud Welding,SAW, etc.

There are many types of welding processes. If you have any questions, please inform us of your workpiece material specifications and requirements. JSR engineers will provide you with professional answers and solution services.

Post time: Dec-21-2023