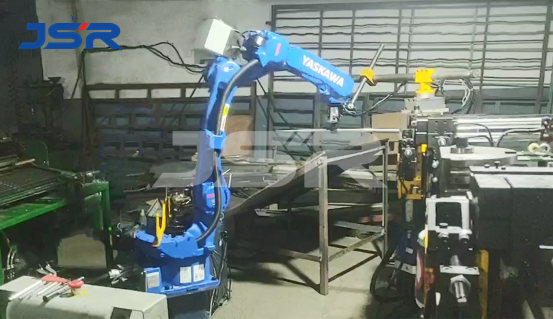

Industrial robots have ultra-high flexibility and precision, low requirements on the working environment, sustainable operation, stable product quality, high efficiency. The factory introduced Yaskawa 6 axis handling robots GP12 to establish automatic assembly line loading and unloading system.

This is a company that deals with bicycle parts, and GP12 works on loading and unloading bicycle handlebars. He needs to move the steel pipe from point A to the pipe bender. After processing, the pipe bender takes it out and moves it to B. It needs to be taken accurately.

Program Implementation:

1. The engineer shall make reasonable layout planning and construction according to the actual working environment of the customer site.

2. Conduct signal interaction wiring according to the signals required by the field external equipment and the robot.

3. Programmed the robot logic program and taught the robot trajectory.

4. Program test runs meet control requirements and production needs.

5. Completed on-site installation and debugging, and provided equipment operation training for customers.

6. After a few days’ work, the on-site equipment has zero failure rate, which can meet the factory’s 24-hour uninterrupted production.

The handling robot reduces the labor intensity of workers, improves production and work efficiency, ensures the personal safety of workers, and realizes automation,intelligence and humanization.Jiesheng is willing to provide customized industrial robot automation solutions for each customer.

Post time: Nov-09-2022