-

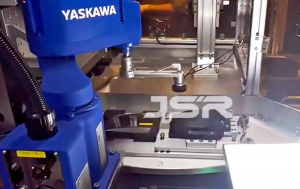

Yaskawa SCARA Robot with 3D Vision: Precision Handling for Car Mirror Lenses

JSR Automation delivers a customized handling solution using a Yaskawa industrial 4-axis SCARA robot for automotive side mirror lens transfer. Equipped with a 3D vision camera, the system detects part position and orientation in real-time, enabling fast and accurate placement. -

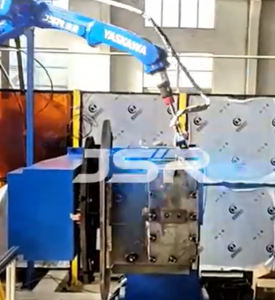

Robotic welding workcell with gantry for large parts

Large Parts? No Problem! Robotic Welding with Gantry How JSR Automation large-scale workpieces are welded efficiently using a robot + gantry structure. Precision, flexibility, and full automation in action. -

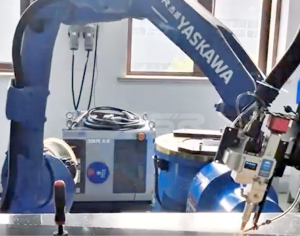

JSR Automation | Yaskawa AR2010 MIG Welding Transformer Enclosures

This is a delivered project by JSR Automation featuring the Yaskawa AR2010 robot for MIG welding transformer enclosures. The system is equipped with a L-type positioner, laser seam tracking, safety fence, light curtain, alarm system, and safety-locked doors, ensuring safe and efficient welding operations. Customized to meet production needs, this solution boosts welding quality, operator safety, and overall efficiency. -

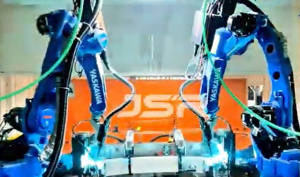

Dual Yaskawa AR1440 Robots MIG Welding Car Bumper Beams

In this project, JSR Automation integrates two Yaskawa AR1440 robots with a 3-axis horizontal rotary positioner to perform simultaneous MIG welding on automotive bumper beams. This setup allows multi-angle, synchronized welding with high efficiency and stability. If your factory is also looking to automate, JSR Automation provides fully customized solutions tailored to your production needs. -

Robot MIG Welding for Auto Parts with Dual-Station Positioner

How JSR Automation uses MIG welding robots to efficiently weld automotive components. Equipped with a dual-station headstock and tailstock positioner, One side loads while the other welds — enabling continuous operation, reducing idle time, and significantly improving production efficiency. -

Industrial robot performs automated random bin picking of bearings

How JSR Automation’s industrial robot performs automated random bin picking of bearings? With vision-guided accuracy and robot smart gripping, it handles disordered parts with ease — no manual sorting needed. This is the future of intelligent material handling. https://youtu.be/fmvmVl8v4JA -

Robot laser welding with filler wire of household kitchen and bathroom product

JSR Automation delivers precise robot laser welding with filler wire, specially designed for household kitchen and bathroom products. This solution ensures smooth, high-quality welds, enhancing both appearance and weld consistency. https://youtu.be/tmXyHafzsvY -

Yaskawa Handling Robot for Motor Rotor Powder Coating Process

JSR Automation integrates Yaskawa handling robots for efficient loading and unloading in the motor rotor powder coating process. The robot ensures stable transfer, precise positioning, and smooth coordination with the coating equipment—enhancing coating uniformity, production efficiency, and automation level. https://youtu.be/rymQwZh2Vzc -

Robotic welding workcell with 7-shaped gantry

JSR Automation‘s robotic welding workcell with a 7-shaped gantry system is designed for welding large workpieces with precision and efficiency. The gantry’s unique 7-shaped structure provides a high degree of freedom and extended reach, allowing the robot to handle larger and more complex components. This setup ensures optimal maneuverability and access to difficult areas, resulting in high-quality welds with reduced cycle times. Ideal for industries with large-scale production, t... -

Three axis positioner robotic welding system

JSR specializes in prodive robotic automation solutions. Our Three-Axis Positioner Robotic Welding System is designed to enhance productivity and streamline operations. Advantages of this robotic welding solution: 1. Two robots weld at the same time greatly improve efficiency, 2. With three-axis positioner make loading and unloading more convenient -

Head and tailstock positioner robotic welding station with robot mounted on RTU track

The head and tailstock positioner robotic welding station, equipped with a robot mounted on an RTU track, offers unmatched flexibility and precision. The track significantly expands the robot’s reach, making it ideal for welding long parts with ease. Additionally, the integration of laser seam tracking ensures precise weld alignment, delivering high-quality results while reducing rework and production time. -

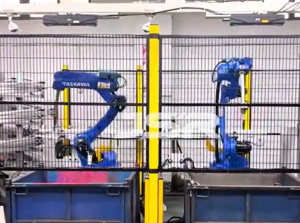

JSR Automation Robot Welding Workstation Project

The JSR Automation robot welding workstation project is currently undergoing testing at our JSR factory. The robot is equipped with a three-axis horizontal rotary positioner and safety system, ensuring precise and efficient welding operations. This setup optimizes the welding process by providing optimal positioning and movement, allowing for high-quality welds and increased productivity. JSR is committed to delivering state-of-the-art automation solutions to meet the evolving needs of our cl...

www.sh-jsr.com

Hot Products - SitemapYaskawa Spot Welding Robot, Robot Palletizer, Palletizing Robot, Welding Robot, Automatic Painting Robot, Yaskawa Painting Robot,

Get the data sheet or free quote

Write your message here and send it to us