Just like a car, half a year or 5,000 kilometers need to be maintained, Yaskawa robot also needs to be maintained, power time and working time to a certain time, also need to be maintained.

The whole machine, parts are the need for regular inspection.

Correct maintenance operation can not only prolong the life of mechanical devices, in the prevention of failure, to ensure safety is also indispensable.

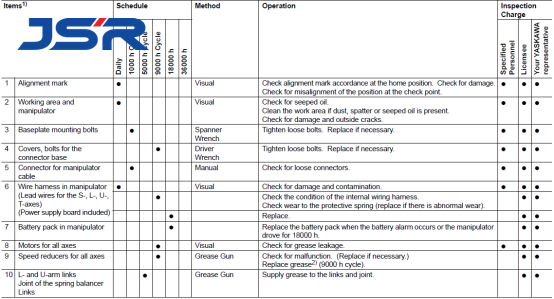

The following table shows the point inspection of a certain type of Yaskawa robot.

Maintenance and overhaul should be carried out by designated professionals. Otherwise, may cause electric shock and personnel injury accident. Please contact us for disassembly and repair of the equipment. Please do not disassemble the motor or lift the lock. Otherwise, it is impossible to predict the rotation direction of the robot arm, which may lead to injuries and other accidents. When carrying out maintenance and overhaul operations, please be sure to install the battery before unplugging the encoder. Otherwise, the origin location data will be lost.

Special points to note:

• If the plug is not removed during refueling, grease may penetrate into the motor, resulting in motor failure. So be sure to remove the stopper.

• Do not install connectors, hoses and other devices at the oil outlet. Otherwise, the oil seal can be damaged and cause fault.

Do not operate by non-professional personnel, otherwise it may cause improper consequences and mechanical damage.

Post time: Nov-09-2022