1. Welding machine and accessories

| Parts | Matters needing attention | Consequences |

| Welder | Do not overload.

The output cable is securely Connected. |

The welder burning.

The welding is unstable and the joint is burned. |

| Welding torch | Replacement parts tip wear must be replaced in time.

Wire feeding sleeve must be cleaned in time. |

The wire feeding is unstable and cannot be welded normally.

High wire feeding resistance, can not be welded normally. |

| Wire feeding device | The pressure adjustment of the arm is consistent with the diameter of the welding wire.

The wire feed pipe must be cleaned in time. |

High wire feeding resistance, can not be welded normally.

High wire feeding resistance, can not be welded normally.

|

| Wire feeding sleeve | The wire feed pipe must be cleaned in time.

The bending radius must not be too small. |

High wire feeding resistance, can not be welded normally.

High wire feeding resistance, can not be welded normally. |

| Wire feeding plate | Pay attention to disc shaft lubrication. | High wire feeding resistance, can not be welded normally. |

2. Analysis of some danger cases on site

Most wire feeding drums have damaged or no lid, and the wire is pulled directly out of the barrel. The serious consequences are:(1) Scratched wire (2) wire feeding is not smooth (3) scratched wire through the wire feeding wheel and wire feeding tube, because the wire feeding is not smooth, the wire coating will fall off and block the wire feeding loop. Lead to welding instability, but also affect the service life of the wire feeding tube and wire feeding wheel!

The wire feed tube is damaged and still in use. The welding wire did not pass through the wire feeder properly. Should be correctly through the wire feeding machine, adjust the corresponding pressure. Serious cause short circuit may burn the robot internal wiring!

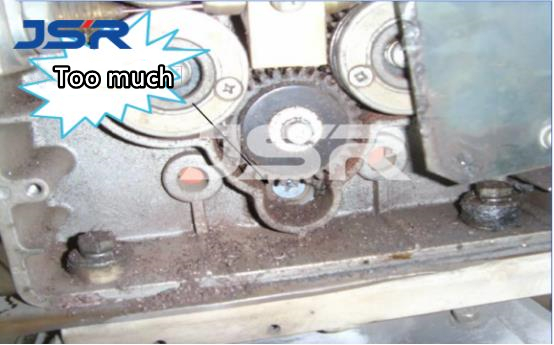

Lots of welding spatter and dust!

The cable is loose, affecting the welding effect. The positive and negative cables of some welders are also loose.

Maintenance + maintenance = benefit

For the professional maintenance of arc welding robot system, please find a professional welding system integration company, Shanghai Jiesheng Welding Technology Co., LTD., engaged in welding system automation integration for more than 10 years, with professional technical personnel and experience.

Post time: Nov-09-2022