Manufacturing Companies for Robotics 4.0 - Yaskawa Spot Welding Robot SP210 – Jiesheng

Manufacturing Companies for Robotics 4.0 - Yaskawa Spot Welding Robot SP210 – Jiesheng Detail:

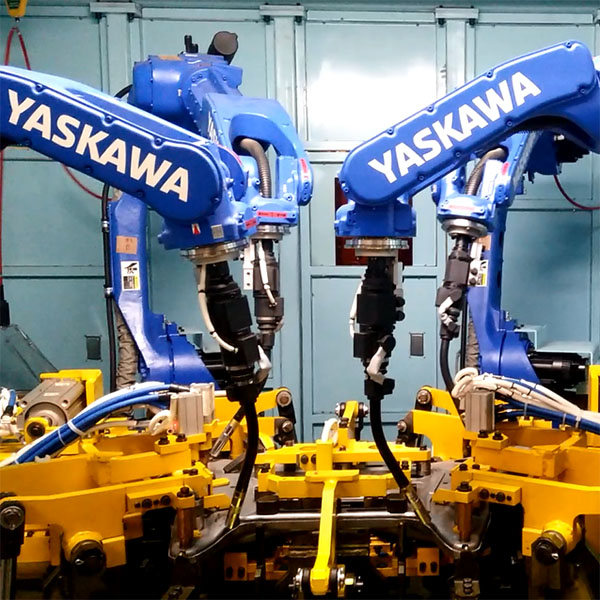

The Yaskawa Spot Welding Robot Workstation SP210 has a maximum load of 210Kg and a maximum range of 2702mm. Its uses include spot welding and handling. It is suitable for electric power, electrical, machinery, and automobile industries. The most used field is the automatic assembly workshop of automobile bodies.

The Yaskawa spot welding robot MOTOMAN-SP210, 6-axis vertical multi-joints makes the robot more flexible and easy to do more actions. Corresponding to the new control cabinet YRC1000, it is a multifunctional robot with higher production efficiency. If manual arc welding is used for shaft welding, the labor intensity of the workers is extremely high, the consistency of the product is poor, and the production efficiency is low. After the automatic welding workstation is adopted, the welding quality and product consistency are also greatly improved.

| Controlled Axes | Payload | Max Working Range | Repeatability |

| 6 | 210Kg | 2702mm | ±0.05mm |

| Weight | Power Supply | S Axis | L Axis |

| 1080Kg | 5.0kVA | 120 °/sec | 97 °/sec |

| U Axis | R Axis | B Axis | T Axis |

| 115 °/sec | 145 °/sec | 145 °/sec | 220 °/sec |

Spot welding robot SP210 performs spot welding operations in accordance with the actions, sequences and parameters specified by the teaching program, and its process is completely automated. And this robot expands the range of motion of the R axis (wrist rotation), B axis (wrist swing), and T axis (wrist rotation) when equipped with a welding gun. The number of dots per robot has been increased, and the production efficiency has been greatly improved.

The spot welding robot workstation includes a control system, a driver, and executive components such as a motor, a mechanical mechanism, and a welding machine system. It can complete the welding work independently, or it can be used in an automated production line as a process part of the welding process, becoming a “station” with welding function on the production line, liberating labor and making production easier and more efficient.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for Manufacturing Companies for Robotics 4.0 - Yaskawa Spot Welding Robot SP210 – Jiesheng, The product will supply to all over the world, such as: Guinea, New York, Israel, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!